C & Z Purlin Roll Forming Machines

C & Z Purlin Roll Forming Machines

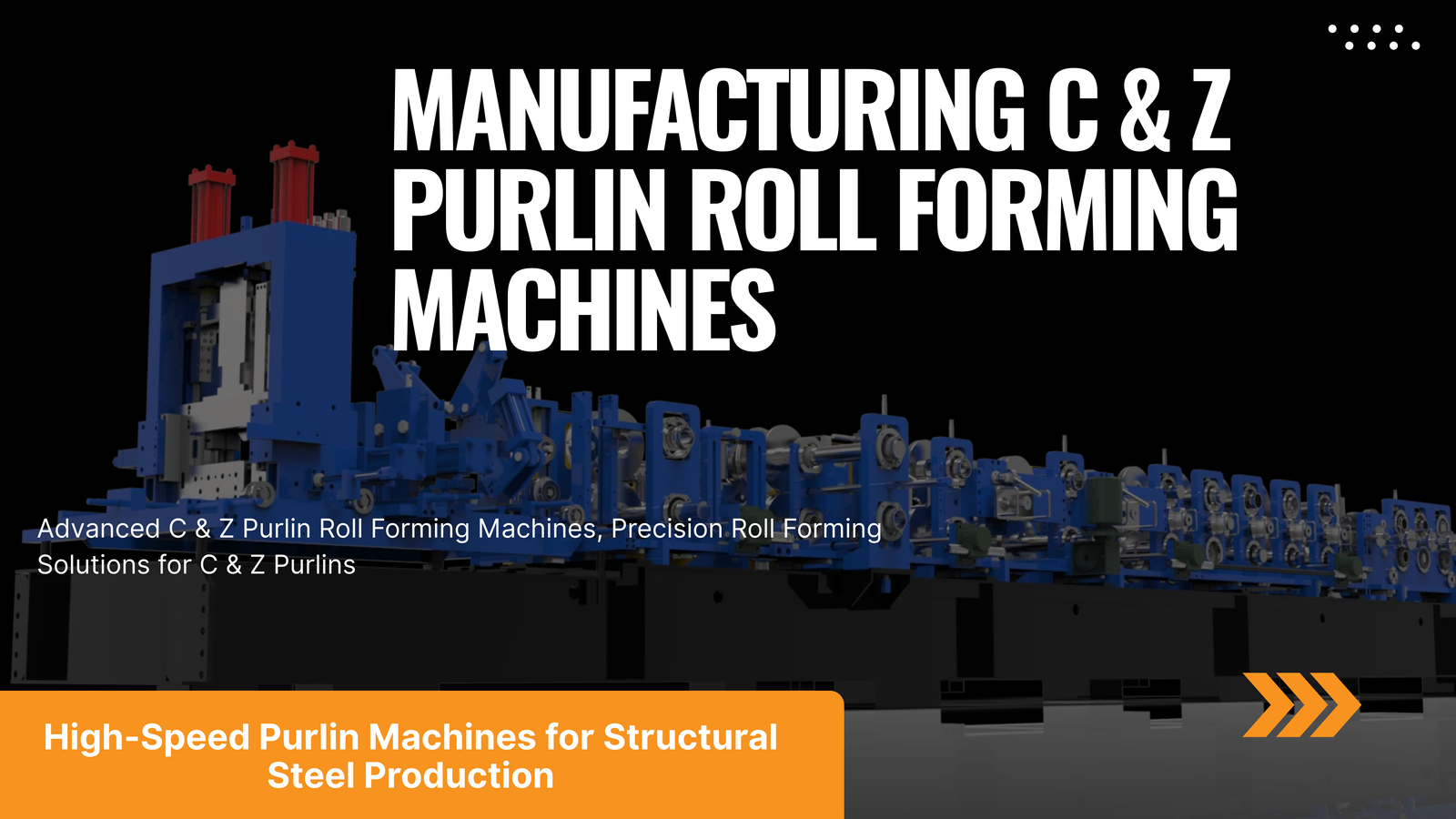

We are a leading Manufacturer of C & Z Purlin Roll Forming Machines, offering high-performance roll forming solutions for the production of structural purlins used in Pre-Engineered Buildings (PEB), warehouses, factory sheds, industrial roofing systems, commercial buildings, and infrastructure projects. Our machines are engineered for high precision, structural consistency, and heavy-duty continuous production.

Designed using advanced CAD/CAM engineering and precision roll tooling systems, our C & Z purlin machines can manufacture multiple profile sizes with optional quick-change or automatic size adjustment systems. The machines are suitable for processing GI, CR, HR, and high-tensile steel coils, ensuring flexibility for diverse structural requirements.

The production line includes hydraulic decoiler, leveling system, servo feeding, hydraulic punching unit, multi-station roll forming system, flying cut-off mechanism, and automatic stacking system. Integrated PLC-based automation ensures synchronized operation, reduced downtime, and high-speed production performance up to 25 meters per minute.

Our machines are built with heavy-duty frames, hardened roll stations, and precision shafts to ensure minimal vibration, high dimensional accuracy, and long operational life.

Key Technical Specifications

-

Material Thickness Range: 1.5 mm – 3.5 mm (customizable)

-

Material Width Capacity: Up to 500 mm (as per profile design)

-

Production Speed: 15–25 meters per minute

-

Forming Stations: 12–20 stations

-

Main Motor Power: 15 HP – 30 HP

-

Hydraulic Power Unit: 7.5 HP – 15 HP

-

Cutting System: Hydraulic / Servo Flying Cut-Off

-

Punching System: Pre-punch / Post-punch hydraulic punching

-

Control System: PLC with HMI Touchscreen

-

Drive Type: Chain Drive / Gear Drive System

-

Shaft Diameter: 70–90 mm hardened shafts

-

Roll Material: EN8 / D2 hardened and polished rolls

-

Decoiler Capacity: 5 Ton – 10 Ton hydraulic decoiler

-

Size Change System: Manual / Semi-automatic / Fully Automatic CZ interchangeable

-

Tolerance Accuracy: ±1 mm profile tolerance

Each machine undergoes trial production runs, dimensional inspection, punching alignment checks, and load testing before dispatch. We also provide complete installation, commissioning, and operator training support.

Our C & Z Purlin Roll Forming Machines deliver high productivity, structural precision, automation efficiency, and long-term durability for modern steel construction industries.