Medical Device Machining Parts

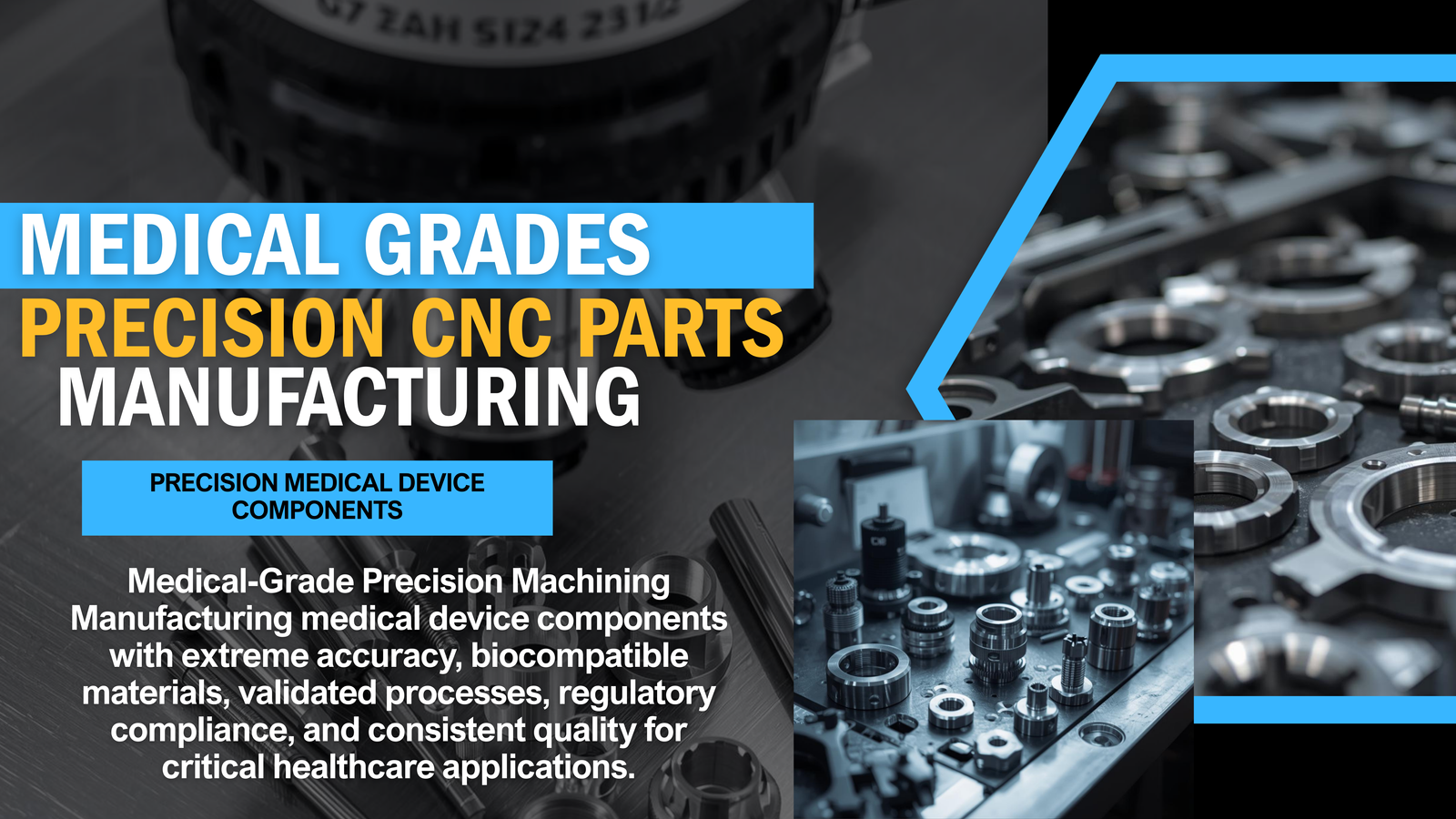

We specialize in delivering comprehensive CNC machining solutions for medical devices and equipment—supporting high-precision components used in diagnostic systems, surgical instruments, implantable devices, therapeutic equipment, and healthcare technology applications. Our manufacturing capabilities focus on micron-level accuracy, repeatable quality, superior surface finish, and contamination-controlled production environments to meet the stringent demands of the medical industry.

Using advanced multi-axis CNC machining centers and precision inspection systems, we manufacture complex components from medical-grade stainless steel, titanium, aluminum alloys, and biocompatible materials. Our engineering approach emphasizes tight tolerances, burr-free machining, smooth surface integrity, and dimensional stability to ensure optimal performance and patient safety. We collaborate with medical OEMs to support both prototyping and scalable production requirements.

Our medical machining processes strictly follow defined inspection protocols, in-process quality control checks, material traceability systems, and final dimensional validation using CMM and precision measuring instruments. We maintain documented quality procedures aligned with healthcare manufacturing standards. We provide end-to-end medical CNC solutions designed to enhance component precision, operational reliability, regulatory compliance, and application safety in critical healthcare environments.