Metal Deck Roll Forming Machines

Metal Deck Roll Forming Machines

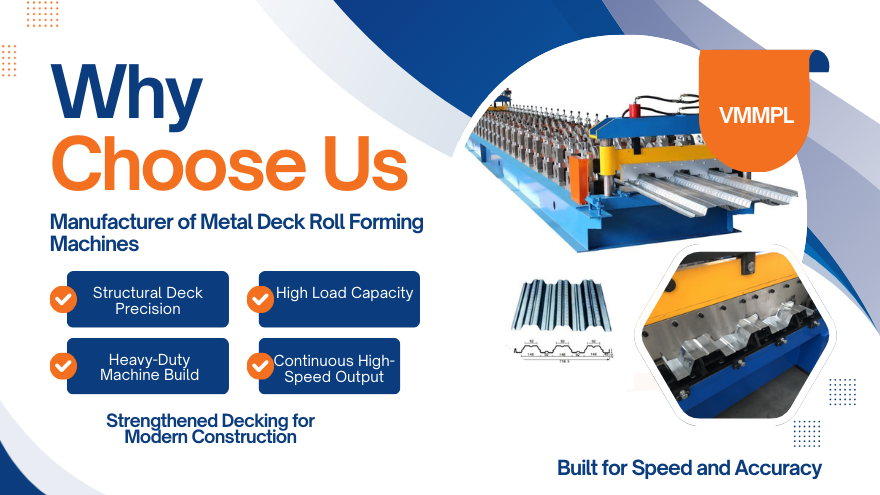

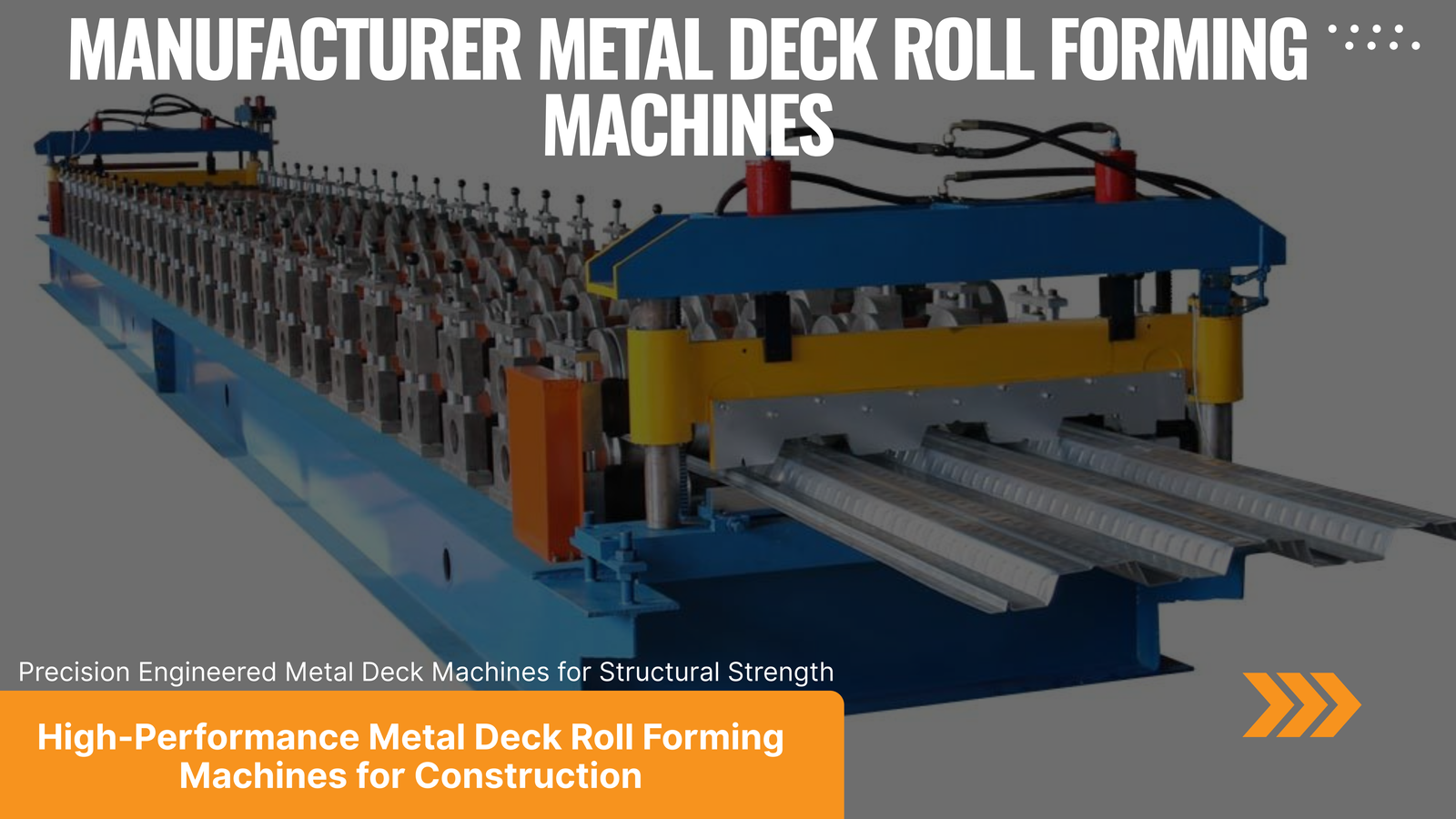

We are a leading Manufacturer of Metal Deck Roll Forming Machines, delivering high-performance roll forming solutions for producing floor decking sheets, composite metal decks, structural deck panels, and roofing deck profiles used in multi-storey buildings, PEB structures, commercial complexes, industrial sheds, bridges, and infrastructure projects. Our machines are engineered for heavy-duty operation, structural precision, and high load-bearing profile production.

Metal deck sheets play a critical role in composite slab construction, providing structural support, reduced concrete consumption, and faster construction timelines. Our roll forming machines are designed using advanced CAD/CAM tooling technology to ensure accurate rib formation, embossing strength, and consistent profile geometry. They are suitable for processing GI, CR, HR, galvanized steel, and high-tensile structural steel coils.

The production line typically includes hydraulic decoiler, coil straightener, servo feeding system, hydraulic punching/embossing unit (optional), multi-station roll forming system, heavy-duty hydraulic cutting system, and automatic stacking system. The machine frame is constructed with reinforced steel to handle thicker materials and maintain vibration-free operation during high-speed production.

Equipped with PLC-based automation and HMI touchscreen control, the system allows precise length setting, punching synchronization, and speed adjustment. Our metal deck machines are capable of producing high rib-height profiles with accurate interlocking systems for superior structural strength.

Each machine undergoes strict trial production runs, load-bearing profile inspection, dimensional verification, embossing alignment checks, and electrical safety validation before dispatch.

Key Technical Specifications

-

Material Thickness Range: 0.8 mm – 2.0 mm

-

Material Width Capacity: Up to 1250 mm

-

Production Speed: 10–20 meters per minute

-

Forming Stations: 16–24 stations

-

Main Motor Power: 20 HP – 40 HP

-

Hydraulic Power Unit: 10 HP – 20 HP

-

Cutting System: Heavy-Duty Hydraulic Cut-Off

-

Punching/Embossing: Optional Hydraulic System

-

Rib Height: 50 mm – 75 mm (customizable)

-

Control System: PLC with HMI Touchscreen

-

Drive Type: Gear Drive / Chain Drive

-

Shaft Diameter: 80–100 mm hardened shafts

-

Roll Material: D2 hardened steel rolls

-

Decoiler Capacity: 5–10 Ton hydraulic decoiler

-

Length Accuracy: ±1 mm

Our Metal Deck Roll Forming Machines are designed for high structural accuracy, heavy-load durability, and long-term production reliability—ideal for modern steel construction and infrastructure industries.