Guard Rail Roll Forming Machines

Guard Rail Roll Forming Machines

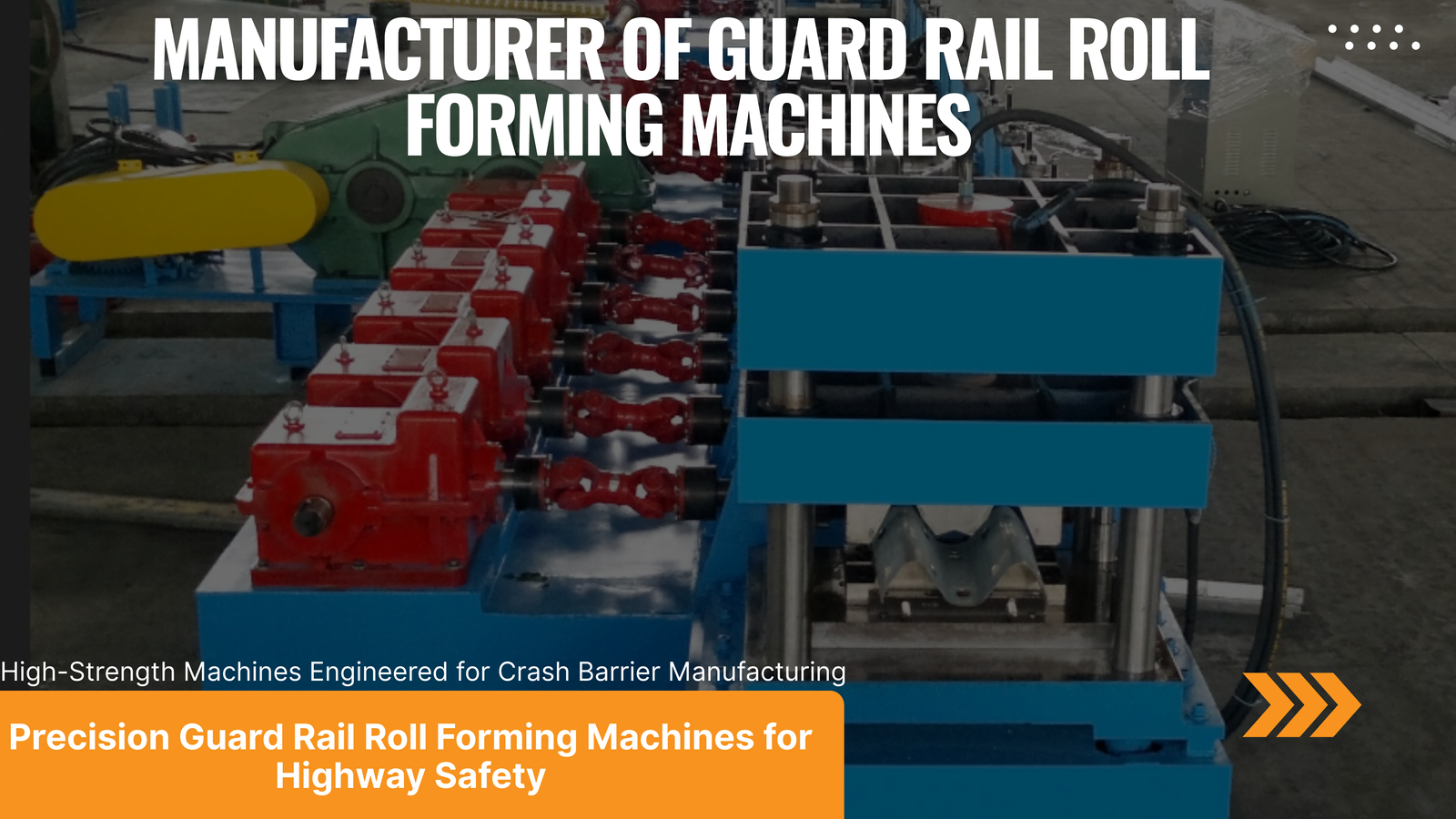

We are a leading Manufacturer of Guard Rail Roll Forming Machines, delivering high-performance roll forming solutions for the production of W-Beam and Thrie-Beam highway guardrails used in expressways, national highways, bridges, flyovers, industrial zones, and infrastructure safety projects. Our machines are engineered to comply with MoRTH, IRC, ASTM, EN, and international road safety standards, ensuring high impact resistance, structural precision, and long-term durability.

Guard rails are critical road safety components designed to absorb collision impact and redirect vehicles safely. Our roll forming machines are developed using advanced CAD-based roll tooling design and structural load analysis, enabling consistent beam corrugation depth, accurate profile shaping, and uniform thickness control. The machines are suitable for processing high-tensile galvanized steel coils, typically ranging from 2.5 mm to 4.0 mm thickness.

The complete production line includes heavy-duty hydraulic decoiler, coil straightening and leveling unit, servo feeding system, high-tonnage hydraulic punching unit (for slots and bolt holes), multi-stage roll forming stations, hydraulic cut-to-length system, and automated stacking system. The reinforced machine frame and hardened forming rolls ensure stable operation with minimal vibration during heavy-load production.

Equipped with PLC-based automation and HMI touchscreen controls, the machine allows precise length setting, synchronized punching alignment, and real-time production monitoring. Optional integration with hot-dip galvanizing plants can be provided for complete guardrail manufacturing solutions.

Each machine undergoes strict trial runs, dimensional inspection, hole alignment verification, load simulation testing, coating compatibility checks, and electrical safety validation before dispatch.

Key Technical Specifications

-

Material Thickness Range: 2.5 mm – 4.0 mm

-

Material Type: High-Tensile Galvanized Steel

-

Profile Type: W-Beam / Thrie-Beam

-

Production Speed: 8–15 meters per minute

-

Forming Stations: 18–26 stations

-

Main Motor Power: 30 HP – 50 HP

-

Hydraulic Power Unit: 15 HP – 25 HP

-

Punching System: Heavy-duty Hydraulic Punching

-

Cutting System: Hydraulic Cut-Off

-

Control System: PLC with HMI Touchscreen

-

Drive Type: Gear Drive System

-

Shaft Diameter: 90–110 mm hardened shafts

-

Roll Material: D2 hardened steel rolls

-

Decoiler Capacity: 10 Ton hydraulic decoiler

-

Length Accuracy: ±1 mm

Our Guard Rail Roll Forming Machines are built for heavy-duty performance, high structural accuracy, impact resistance compliance, and long-term reliability—ideal for large-scale highway and infrastructure safety manufacturing projects.