Metal Roof Roll Forming Machines

Metal Roof Roll Forming Machines

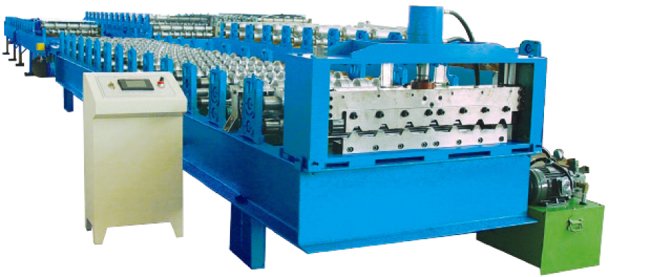

We are a leading Manufacturer of Metal Roof Roll Forming Machines, delivering high-performance roll forming solutions for producing corrugated roofing sheets, trapezoidal roof panels, ribbed metal roofing, color-coated sheets, and industrial cladding profiles. Our machines are engineered to ensure dimensional precision, high-speed production, smooth surface finish, and long-term operational reliability for roofing sheet manufacturers.

Metal roofing sheets are widely used in pre-engineered buildings (PEB), warehouses, factory sheds, commercial complexes, residential roofing, cold storage units, and infrastructure projects due to their durability and weather resistance. Our roll forming machines are developed using advanced CAD/CAM profile design and precision tooling technology, ensuring accurate rib depth, consistent pitch formation, and uniform sheet geometry.

The production line typically includes hydraulic decoiler, coil leveling system, servo feeding unit, multi-stage roll forming stations, hydraulic or servo cut-to-length system, and automatic run-out table or stacking unit. Our machines are capable of processing GI, PPGI, PPGL, CR, aluminum, and other coated metal sheets, ensuring versatility across roofing applications.

Equipped with PLC-based automation and HMI touchscreen interface, operators can easily set sheet length, production speed, and cutting parameters with high accuracy. The heavy-duty machine frame, hardened forming rolls, and precision shafts ensure vibration-free operation and stable production speeds up to 30 meters per minute.

Each machine undergoes strict trial production runs, profile dimension inspection, rib alignment verification, sheet thickness checks, and electrical safety testing before dispatch to ensure consistent field performance.

Key Technical Specifications

-

Material Thickness Range: 0.3 mm – 1.2 mm

-

Material Type: GI / PPGI / PPGL / Aluminum

-

Material Width Capacity: Up to 1250 mm

-

Production Speed: 15–30 meters per minute

-

Forming Stations: 12–18 stations

-

Main Motor Power: 7.5 HP – 20 HP

-

Hydraulic Power Unit: 5 HP – 10 HP

-

Cutting System: Hydraulic / Servo Fixed-Length Cut-Off

-

Control System: PLC with HMI Touchscreen

-

Drive Type: Chain Drive / Gear Drive

-

Shaft Diameter: 60–80 mm hardened shafts

-

Roll Material: EN8 / D2 hardened steel rolls

-

Decoiler Capacity: 5 Ton hydraulic decoiler

-

Length Accuracy: ±1 mm

-

Power Supply: 415V, 3-Phase, 50 Hz

Our Metal Roof Roll Forming Machines deliver high productivity, precise profile accuracy, low maintenance, and long-term durability—making them ideal for modern roofing sheet manufacturing industries.