Precision Steel for Roads, Solar, and Structures

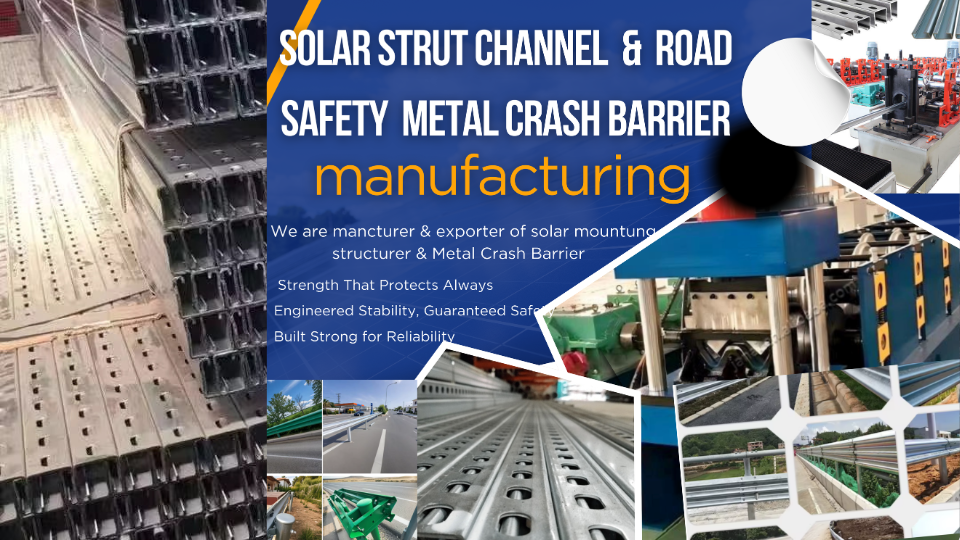

We specialize in delivering comprehensive Steel Infrastructure Manufacturing Solutions supporting Solar Mounting Strut Channels, Highway Metal Road Crash Barriers, and Industrial Structural Projects—from detailed engineering design and precision roll forming to advanced fabrication, surface finishing, and timely supply. Our steel infrastructure components are engineered for high load-bearing capacity, structural stability, corrosion resistance, and long-term durability under demanding environmental and operational conditions.

Equipped with advanced roll forming lines, CNC-controlled cutting and punching systems, automated welding stations, and hot-dip galvanizing processes, we manufacture solar mounting structures, 41×41 & customized strut channels, W-beam & Thrie-beam crash barriers, guardrail systems, steel posts, spacer blocks, gantry structures, and heavy-duty structural assemblies. Our engineering team performs optimized structural calculations, wind-load validation, and coating thickness verification in compliance with IS, ASTM, MoRTH, and international standards.

Our manufacturing processes follow strict raw material traceability, thickness and zinc coating inspections, dimensional tolerance checks, load-bearing validation, and batch quality documentation protocols at every stage of production.

We provide end-to-end steel structure and infrastructure manufacturing solutions designed to ensure safety, precision fitment, impact resistance, regulatory compliance, and long-term reliability for critical solar, highway, and industrial infrastructure projects.