Cable Tray Roll Forming Machines

Cable Tray Roll Forming Machines

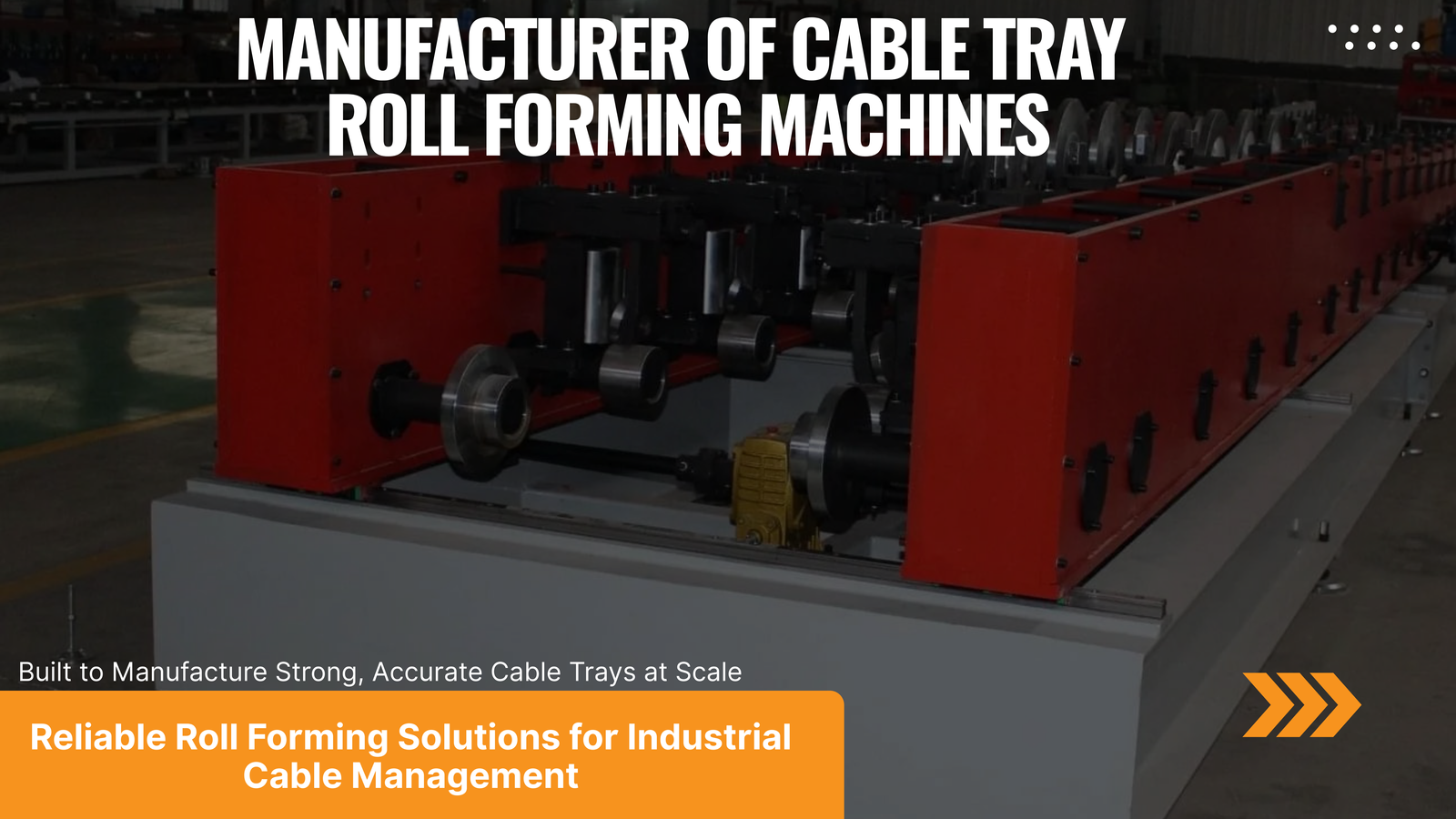

We are a leading Manufacturer of Cable Tray Roll Forming Machines, delivering precision-engineered roll forming solutions for the production of perforated cable trays, ladder-type cable trays, GI cable trays, powder-coated trays, and customized electrical support systems used in industrial plants, commercial buildings, power projects, telecom infrastructure, and data centers. Our machines are designed to ensure high dimensional accuracy, uniform perforation alignment, and long-term structural durability.

Cable trays are critical components for organized cable management and safe electrical routing. Our roll forming machines are developed using advanced CAD-based tooling design and precision roll forming technology to produce consistent tray profiles with smooth edges and precise bend angles. The machines can process GI, CR, HR, stainless steel, aluminum, and coated sheets, typically ranging from 1.0 mm to 3.0 mm thickness.

The production line includes hydraulic decoiler, leveling system, servo feeding unit, high-precision punching system for perforations, multi-stage roll forming stations, hydraulic cut-to-length system, and automatic stacking unit. The punching system ensures accurate hole placement for cable ventilation, load support, and installation compatibility.

Our machines are equipped with PLC-based automation and HMI touchscreen control, allowing automatic length setting, perforation programming, and synchronized production. The heavy-duty base frame, hardened forming rolls, and precision-ground shafts ensure vibration-free operation and high-speed performance up to 20 meters per minute.

Each machine undergoes strict trial production runs, perforation alignment verification, dimensional inspection, structural load validation, and electrical safety testing before dispatch.

Key Technical Specifications

-

Material Thickness Range: 1.0 mm – 3.0 mm

-

Material Type: GI / CR / SS / Aluminum

-

Production Speed: 10–20 meters per minute

-

Forming Stations: 14–20 stations

-

Main Motor Power: 15 HP – 30 HP

-

Hydraulic Power Unit: 7.5 HP – 15 HP

-

Punching System: Hydraulic / CNC Punching

-

Cutting System: Hydraulic Cut-Off

-

Control System: PLC with HMI Touchscreen

-

Drive Type: Chain / Gear Drive

-

Shaft Diameter: 70–90 mm hardened shafts

-

Roll Material: EN8 / D2 hardened rolls

-

Decoiler Capacity: 5–7 Ton hydraulic decoiler

-

Tray Width Capacity: 100 mm – 600 mm (customizable)

-

Length Accuracy: ±1 mm

Our Cable Tray Roll Forming Machines are engineered for high productivity, precise perforation control, structural strength, and long-term manufacturing reliability—ideal for electrical infrastructure and industrial cable management industries.