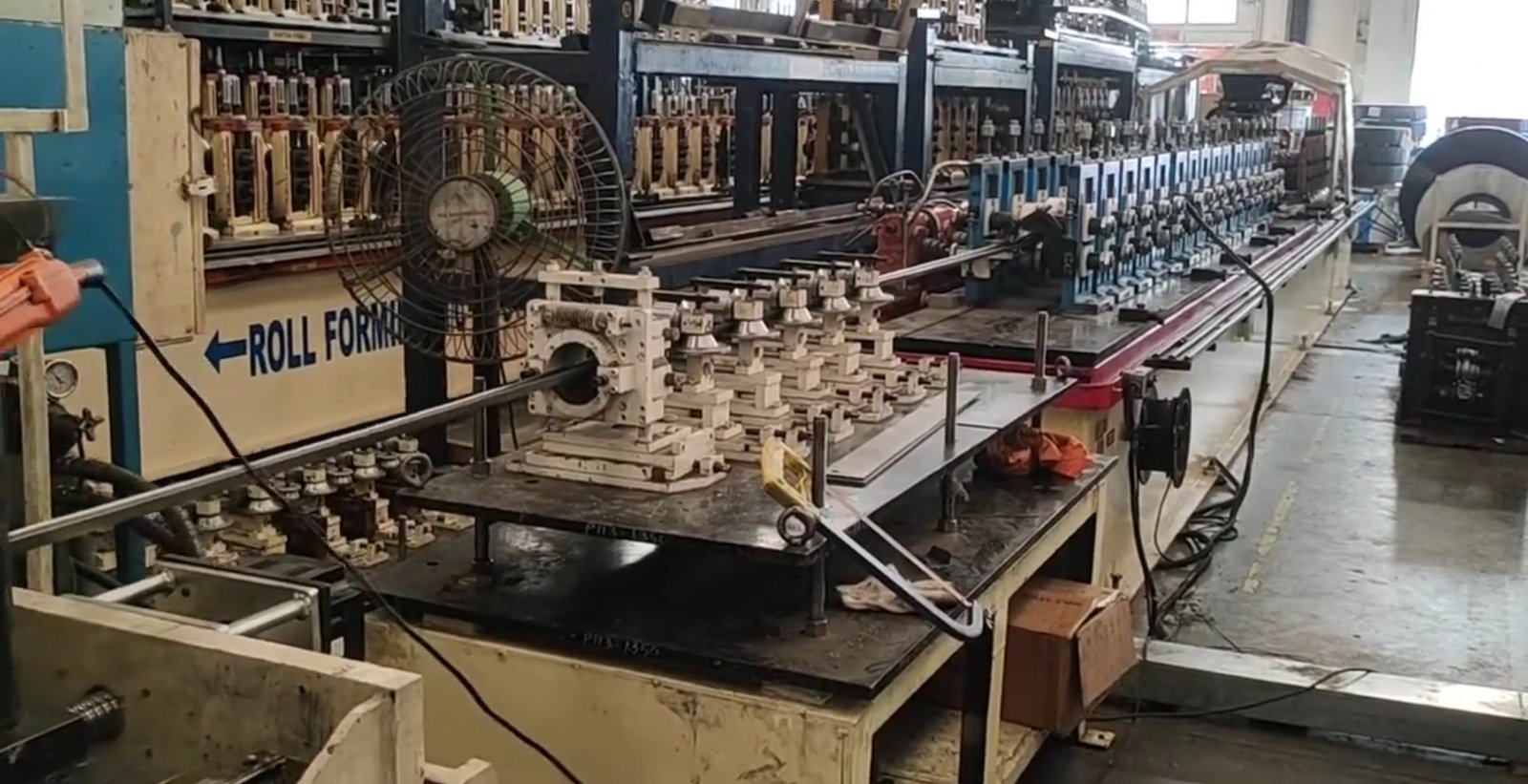

Four Wheeler Door Sash Roll Forming Machine

Four Wheeler Door Sash Roll Forming Machine

We are a leading Manufacturer of Four Wheeler Door Sash Roll Forming Machines, delivering precision-engineered roll forming solutions for producing automotive door sash profiles, window frame channels, reinforcement sections, and structural frame components used in passenger cars and light commercial vehicles. Our machines are designed to meet stringent automotive manufacturing standards, ensuring high dimensional accuracy, structural consistency, and superior surface finish.

Automotive door sash components require tight tolerances and consistent geometry to ensure proper fitment, smooth window movement, and structural integrity. Our roll forming machines are developed using advanced CAD/CAM tooling design and precision engineering techniques, enabling accurate profile shaping and repeatable production. The machines are capable of processing CR steel, high-tensile steel, galvanized steel, and coated automotive-grade sheets, typically ranging from 0.8 mm to 2.5 mm thickness.

The production line integrates hydraulic decoiler, strip leveling unit, servo feeding system, precision punching system for slots and mounting holes, multi-stage roll forming stations, hydraulic or servo cut-to-length system, and profile discharge unit. The punching system ensures accurate alignment for hinges, glass channel guides, and assembly points.

Equipped with PLC-based automation and HMI touchscreen interface, the system allows precise control of profile dimensions, punching positions, production speed, and length settings. The heavy-duty frame structure, hardened roll tooling, and synchronized drive mechanism ensure vibration-free operation and long-term durability.

Each machine undergoes comprehensive trial production runs, profile dimension verification, hole alignment inspection, bend angle validation, surface finish checks, and electrical safety testing before dispatch.

Key Technical Specifications

-

Material Thickness Range: 0.8 mm – 2.5 mm

-

Material Type: CR / High-Tensile / GI Automotive Steel

-

Production Speed: 10–20 meters per minute

-

Forming Stations: 14–20 stations

-

Main Motor Power: 15 HP – 30 HP

-

Hydraulic Power Unit: 7.5 HP – 15 HP

-

Punching System: Hydraulic / CNC Punching

-

Cutting System: Servo / Hydraulic Cut-Off

-

Control System: PLC with HMI Touchscreen

-

Drive Type: Gear Drive / Chain Drive

-

Shaft Diameter: 70–90 mm hardened shafts

-

Roll Material: D2 hardened steel rolls

-

Decoiler Capacity: 3–5 Ton hydraulic decoiler

-

Tolerance Accuracy: ±0.5 mm

-

Power Supply: 415V, 3-Phase, 50 Hz

Our Four Wheeler Door Sash Roll Forming Machine ensures automotive-grade precision, smooth surface finish, high repeatability, and long-term production reliability—ideal for OEM and Tier-1 automotive component manufacturers.