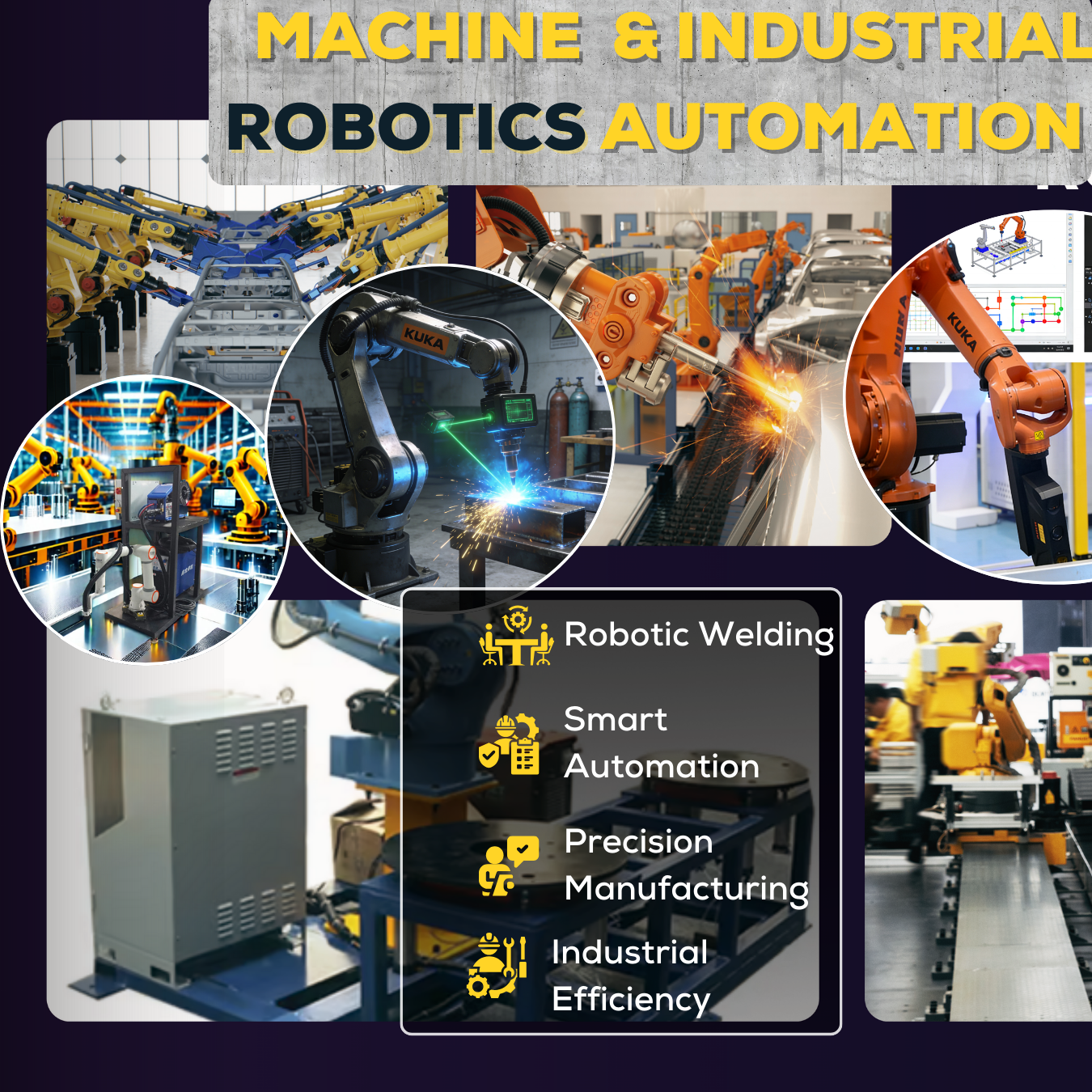

Robotics and Automation Redefined

We specialize in delivering comprehensive Industrial Automation & Robotic Welding Solutions, covering the complete lifecycle—from system concept design, electrical engineering, control panel development, and PLC programming to system integration, installation, commissioning, and long-term technical support. Our automation systems are engineered to optimize productivity, enhance workplace safety, reduce manual dependency, and ensure consistent, high-precision process performance across diverse manufacturing environments.

With strong expertise in robotic welding cells, PLC & SCADA automation systems, servo-driven motion control, conveyor automation, material handling integration, and customized Special Purpose Machines (SPMs), we develop intelligent automation platforms tailored to client-specific production workflows. Our solutions are designed to reduce cycle time, minimize rejection rates, improve weld consistency, enhance repeatability, and support scalable high-volume manufacturing operations. We integrate advanced sensors, HMI interfaces, IoT-enabled monitoring systems, data analytics dashboards, and predictive maintenance modules to enable real-time performance tracking and smart factory transformation.

Our automation systems follow structured programming standards, simulation testing, safety interlock validation, load trials, and multi-stage commissioning procedures before final deployment. Each project undergoes rigorous performance testing to ensure seamless integration with existing production lines.

We provide end-to-end Industrial Automation & Robotic Welding Solutions designed to enhance manufacturing efficiency, operational stability, cost optimization, energy efficiency, and long-term industrial competitiveness in modern Industry 4.0 environments.

.png)